- Home Page

- Company Profile

-

Our Products

- PTFE Sheets

- PTFE Molded Sheet

- 3 mm PTFE Expanded Sheet

- White PTFE Skived Sheet

- 6 Mm PTFE Sheet

- 1000 Mm PTFE Skived Sheet

- 600 Mm PTFE Skived Sheet

- 1200 Mm PTFE Sheet

- 600 Mm Skived PTFE Sheet

- 450 Mm PTFE Skived Sheet

- 300 Mm PTFE Molded Sheet

- 5 Mm Expanded PTFE Sheet

- 450 Mm PTFE Sheet

- Expanded PTFE Sheet

- White Expanded PTFE Sheet

- 3 Mm Thick PTFE Sheet

- PTFE Sheet

- PTFE Sheet 6mm

- PTFE Sheet 8mm

- PCTFE SHEET

- PVDF Sheet

- PFA Sheet

- FEP Sheet

- PTFE Bushes

- PTFE Rods

- PTFE Tubes

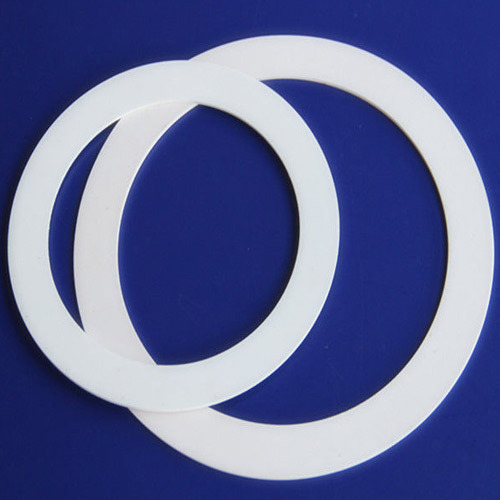

- PTFE Gaskets

- PTFE Machined Components

- PTFE Plate

- PTFE Washers

- PTFE Ball

- PTFE Bellow

- Turcite Sheet Roll

- PTFE Seals

- PTFE Bar

- PTFE Skived Sheet

- Teflon Sheets

- Teflon Rods

- PTFE O Ring

- Bridge Bearing Pads

- PEEK Rod

- PEEK Products

- PTFE Sheets

- Extra Links

- Contact Us

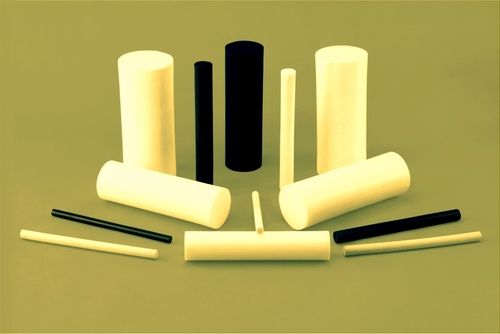

PTFE Bar

600.00 - 750.00 INR/Kilograms

Product Details:

- Type PTFE Bar

- Material Virgin PTFE (Polytetrafluoroethylene)

- Working Temperature -200C to +260C

- Density 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection Excellent chemical resistance

- Tensile Strength 20 - 30 MPa

- Thickness As per diameter

- Click to View more

X

PTFE Bar Price And Quantity

- 50 Kilograms

- 600.00 - 750.00 INR/Kilograms

PTFE Bar Product Specifications

- 300 mm to 1000 mm or custom

- 20 - 30 MPa

- 5 mm to 200 mm diameter

- As per diameter

- PTFE Bar

- -200C to +260C

- Excellent chemical resistance

- Customizable / As per requirement

- 327C

- 2.3 Gram per cubic centimeter(g/cm3)

- Virgin PTFE (Polytetrafluoroethylene)

PTFE Bar Trade Information

- 10 Kilograms Per Day

- 1-2 Week

Product Description

Sanghvi Techno Products is an ISO 9001:2015 certified producer of PTFE rods in different colors and sizes. The Ahmedabad, Gujarat (India) based company makes sure the rods delivered are chemical resistant, flame resistant, non sticky, UV resistant, and aging resistant. The operators can easily machine the PTFE rod, as PTFE is the easiest plastic type to work upon. The technicians can even machine it to close tolerances. The rod gets all performance characteristics from the material. The applications of these rods can be machined components and products. Customers can get in touch with us with their requirement for the product and their specific sizes.

PTFE Bar provided by our company, has high temperature and chemical resistance, it is usually used for valve applications. This bar is manufactured and designed by our skilled workers using optimum quality raw materials and latest machines. This bar is safe to use and used in various industries. Our PTFE Bar is very cost effective and can be easily availed at nominal pricing, by our valued customers, in bulk quantities.

Technical details

Diameter | 16 - 400 mm |

Shape | Round |

Style | Molded |

Rod Height | 30 to 50 mm |

Technique | Compression Molding |

Color | White |

Brand | STP |

Density | 2.1 - 2.2 |

Melting Point | 350 deg C |

Operating Temperature | 250 deg C |

Pattern | Round |

Material | Glass Filled PTFE |

Length | 300 mm - 500 mm |

Superior Chemical and Corrosion Resistance

PTFE bars exhibit remarkable resistance to most chemicals and solvents, making them ideal for environments where corrosive substances are present. Their non-reactive nature ensures a long operational lifespan, even under aggressive conditions, safeguarding both equipment and processes.

Exceptional Electrical Insulation

With excellent dielectric properties, these PTFE rods are widely used for electrical insulation in high-voltage equipment. Their stability, even at extreme temperatures, ensures consistent performance and safety for electronic and electrical applications.

Food-Grade Safety and Compliance

Manufactured using virgin PTFE, these bars meet FDA standards, making them suitable for direct contact with food. Their non-stick and non-absorbent qualities are especially advantageous for food processing and packaging both in industrial kitchens and production lines.

FAQs of PTFE Bar:

Q: How can PTFE bars be machined for different applications?

A: PTFE bars feature excellent machinability, enabling users to easily cut, shape, turn, or mill them into custom components for a variety of industrial, electrical, or food-contact applications. Standard machining tools are typically used.Q: What makes PTFE bars suitable for use in food processing environments?

A: Virgin PTFE bars comply with FDA requirements for food contact, exhibit non-absorbent and non-stick properties, and are resistant to contamination and chemical attack, making them safe and reliable for use in food processing and handling.Q: When should PTFE bars be chosen over other engineering plastics?

A: PTFE bars are recommended when superior chemical resistance, high temperature tolerance (up to +260C), and excellent dielectric properties are required. They are particularly advantageous in situations where non-flammability and low water absorption are essential.Q: Where are PTFE rods commonly applied in industry?

A: These PTFE bars are used in diverse sectors including chemical processing, electrical insulation, sealing and gasket manufacturing, food processing, and laboratory equipment due to their stable performance in harsh environments.Q: What is the process for customizing PTFE rods to specific sizes?

A: Manufacturers can supply PTFE bars in diameters ranging from 5 mm to 200 mm and lengths between 300 mm and 1000 mm or as per customer specifications, ensuring each order meets unique project requirements.Q: What benefits does the smooth surface finish of PTFE bars provide?

A: A smooth surface minimizes friction and prevents material adherence, critical for applications where cleanliness, low maintenance, and efficient movement or sealing are required, such as in food and chemical industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

SANGHVI TECHNO PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |