- Home Page

- Company Profile

-

Our Products

- PTFE Sheets

- PTFE Molded Sheet

- 3 mm PTFE Expanded Sheet

- White PTFE Skived Sheet

- 6 Mm PTFE Sheet

- 1000 Mm PTFE Skived Sheet

- 600 Mm PTFE Skived Sheet

- 1200 Mm PTFE Sheet

- 600 Mm Skived PTFE Sheet

- 450 Mm PTFE Skived Sheet

- 300 Mm PTFE Molded Sheet

- 5 Mm Expanded PTFE Sheet

- 450 Mm PTFE Sheet

- Expanded PTFE Sheet

- White Expanded PTFE Sheet

- 3 Mm Thick PTFE Sheet

- PTFE Sheet

- PTFE Sheet 6mm

- PTFE Sheet 8mm

- PCTFE SHEET

- PVDF Sheet

- PFA Sheet

- FEP Sheet

- PTFE Bushes

- PTFE Rods

- PTFE Tubes

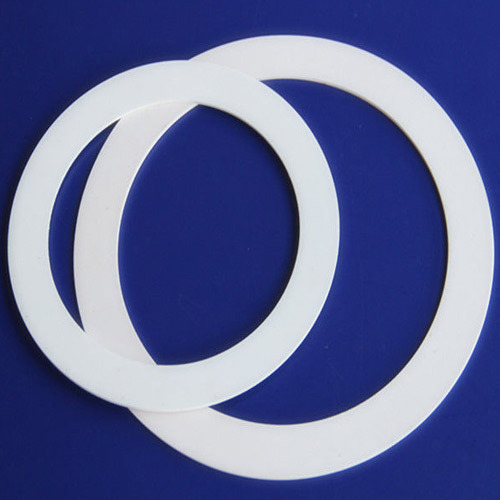

- PTFE Gaskets

- PTFE Machined Components

- PTFE Plate

- PTFE Washers

- PTFE Ball

- PTFE Bellow

- Turcite Sheet Roll

- PTFE Seals

- PTFE Bar

- PTFE Skived Sheet

- Teflon Sheets

- Teflon Rods

- PTFE O Ring

- Bridge Bearing Pads

- PEEK Rod

- PEEK Products

- PTFE Sheets

- Extra Links

- Contact Us

PTFE Sleeves Tubes

1500 INR/Kilograms

Product Details:

- Product Type Sleeves Tubes

- Material PTFE (Polytetrafluoroethylene)

- Type Extruded Sleeves

- Shape Tube / Sleeve

- Technique Extrusion Process

- Surface Treatment Smooth Finish

- Standard ASTM D3294

- Click to View more

X

PTFE Sleeves Tubes Price And Quantity

- 10 Kilograms

- 1500 INR/Kilograms

PTFE Sleeves Tubes Product Specifications

- 0.5 mm to 5 mm

- ASTM D3294

- 4 mm to 30 mm

- Custom Sizes Available

- 2 mm to 25 mm

- PTFE (Polytetrafluoroethylene)

- 100 mm to 1000 mm

- Virgin PTFE

- White

- Extrusion Process

- Extruded Sleeves

- Tube / Sleeve

- 25 MPa

- Sleeves Tubes

- Smooth Finish

PTFE Sleeves Tubes Trade Information

- 10 Kilograms Per Day

- 1-2 Week

Product Description

PTFE Sleeve Tubes are a semi-transparent, chemically inert, and non-toxic material that features unmatched temperature resistance and a surface that facilitates the flow of fluids. These PTFE tubes are used applications requiring resistance to high temperatures, corrosive chemicals, and high voltages. Polytetrafluoroethylene Sleeve Tubes use in fluid transfer applications, cabling, and heat-exchanger systems. PTFE can be used in service temperatures of up to 260°C, making it a material of choice in high temperature applications. We manufacture various grades and sizes of tubes, making them ideal for medical, chemical, and automotive applications. These tubes are very economical and can be easily purchased by our esteemed customers at reasonable rates, in bulk quantities.

Technical details

Inner Diameter | 1.6 mm to 90 mm (Standard) |

Color | White |

Brand | STP |

Outer Diameter | 3.2 mm to 100 mm (Standard) |

Model No. | ASTM - D-3295 |

Length | 1000 mm (Standard) |

Premium Quality Virgin PTFE Material

Crafted using extruded virgin PTFE, these sleeves exhibit exceptional nonstick and non-reactive characteristics, making them ideal for use in sensitive environments. The smooth surface treatment enhances their resistance to chemicals and contamination, while preserving their high dielectric performance.

Wide Temperature and Chemical Compatibility

Meeting stringent industrial standards, PTFE tubes are designed to withstand extreme temperatures ranging from -200C to +260C and offer excellent resistance to nearly all chemicals. These properties ensure reliable performance across a broad spectrum of demanding applications.

Versatile Application Scope and Customization

PTFE sleeves are extensively used in insulation for electrical components, fluid transfer in the chemical and pharmaceutical sectors, and food processing environments. Available in multiple diameters, wall thicknesses, and lengths, customization is possible to cater to precise operational requirements.

FAQ's of PTFE Sleeves Tubes:

Q: How are PTFE sleeves tubes manufactured?

A: PTFE sleeves tubes are produced through an extrusion process. Virgin PTFE resin is extruded into the desired tube or sleeve shape, ensuring consistency in wall thickness and surface smoothness as per ASTM D3294 standards.Q: What benefits do PTFE sleeves tubes offer over other materials?

A: These sleeves provide superior chemical and temperature resistance, outstanding electrical insulation, and are non-flammable. Their high flexibility and smooth finish also ensure reliable operation in harsh and sensitive environments.Q: Where can PTFE sleeves tubes be applied?

A: PTFE sleeves tubes are widely used in electrical insulation, chemical processing, pharmaceutical manufacturing, and food industries, due to their inertness, durability, and ability to withstand extreme operating conditions.Q: When should PTFE sleeves tubes be chosen for a project?

A: Opt for PTFE sleeves tubes when your application demands excellent chemical resistance, superior dielectric strength, performance under extreme temperatures, and strict food or pharmaceutical safety requirements.Q: What sizes and customization options are available for PTFE sleeves tubes?

A: PTFE sleeves tubes can be customized with inside diameters from 2 mm to 25 mm, outer diameters from 4 mm to 30 mm, wall thicknesses between 0.5 mm and 5 mm, and lengths ranging from 100 mm to 1000 mm to meet specific project needs.Q: How do PTFE sleeves tubes enhance safety in industrial applications?

A: PTFE sleeves are inherently non-flammable and maintain stability in high-temperature environments, reducing fire risks. Their exceptional chemical resistance prevents degradation from corrosive substances, ensuring safer equipment operation.Q: What is the process for ordering custom PTFE sleeves tubes from an exporter or manufacturer in India?

A: To order custom PTFE sleeves tubes, specify your required dimensions, grade, and application. Manufacturers or exporters in India will tailor the extruded tubes to your specifications, ensuring product compliance with industry standards and timely delivery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PTFE Tubes' category

|

SANGHVI TECHNO PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |