- Home Page

- Company Profile

-

Our Products

- PTFE Sheets

- PTFE Molded Sheet

- 3 mm PTFE Expanded Sheet

- White PTFE Skived Sheet

- 6 Mm PTFE Sheet

- 1000 Mm PTFE Skived Sheet

- 600 Mm PTFE Skived Sheet

- 1200 Mm PTFE Sheet

- 600 Mm Skived PTFE Sheet

- 450 Mm PTFE Skived Sheet

- 300 Mm PTFE Molded Sheet

- 5 Mm Expanded PTFE Sheet

- 450 Mm PTFE Sheet

- Expanded PTFE Sheet

- White Expanded PTFE Sheet

- 3 Mm Thick PTFE Sheet

- PTFE Sheet

- PTFE Sheet 6mm

- PTFE Sheet 8mm

- PCTFE SHEET

- PVDF Sheet

- PFA Sheet

- FEP Sheet

- PTFE Bushes

- PTFE Rods

- PTFE Tubes

- PTFE Gaskets

- PTFE Machined Components

- PTFE Plate

- PTFE Washers

- PTFE Ball

- PTFE Bellow

- Turcite Sheet Roll

- PTFE Seals

- PTFE Bar

- PTFE Skived Sheet

- Teflon Sheets

- Teflon Rods

- PTFE O Ring

- Bridge Bearing Pads

- PEEK Rod

- PEEK Products

- PTFE Sheets

- Extra Links

- Contact Us

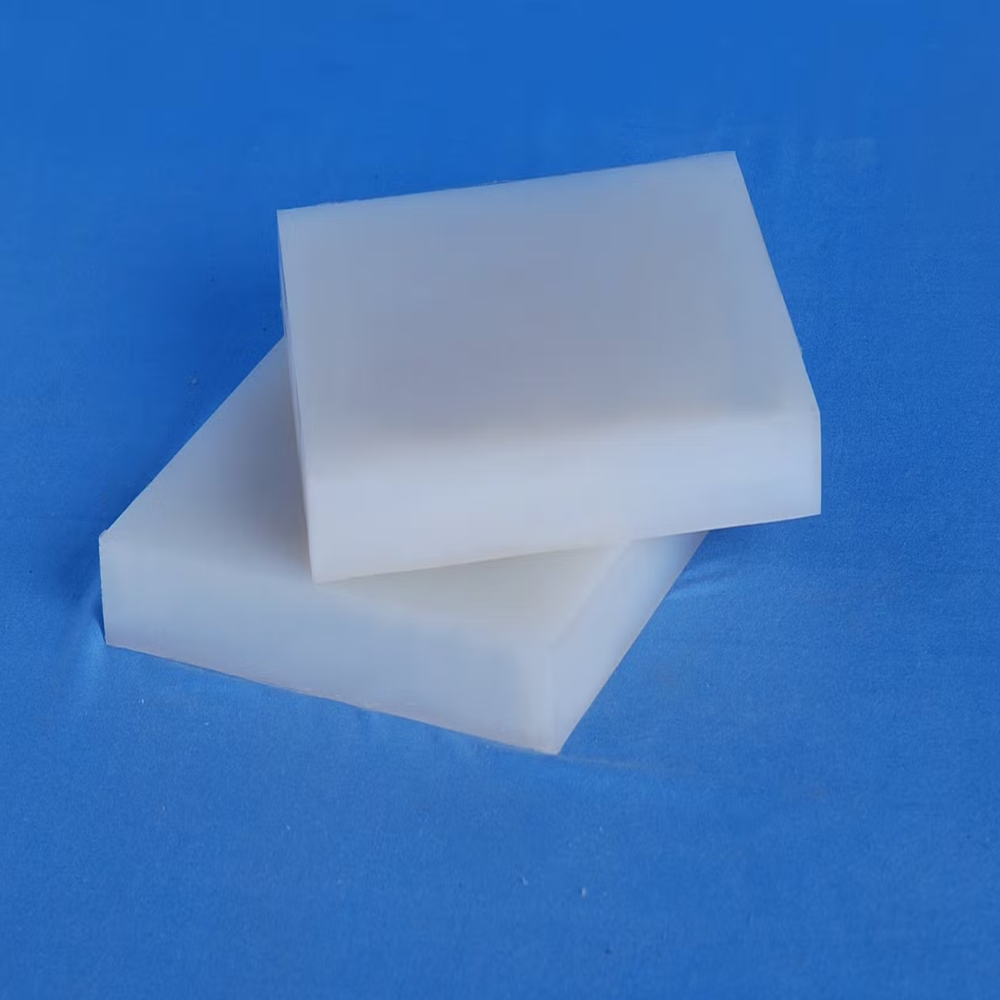

PVDF Sheet

1700.0 INR/Kilograms

Product Details:

- Type PVDF Sheet

- Material PVDF

- Working Temperature 140 Celsius (oC)

- Density 1.78 Gram per cubic centimeter(g/cm3)

- Corrosion Protection Yes

- Size Different Available

- Click to View more

X

PVDF Sheet Price And Quantity

- 1 Kilograms

- 1700.0 INR/Kilograms

PVDF Sheet Product Specifications

- PVDF

- Different Available

- 140 Celsius (oC)

- 1.78 Gram per cubic centimeter(g/cm3)

- Yes

- PVDF Sheet

PVDF Sheet Trade Information

- Telegraphic Transfer (T/T)

- 10 Kilograms Per Month

- 2 Week

- No

- Standard Corrugated box.

- All India

Product Description

PVDF (Polyvinylidene Fluoride) products exhibit exceptional chemical resistance, high mechanical strength, UV and weather resistance, and good abrasion resistance. They retain their properties over a wide temperature range and offer excellent flame resistance. PVDF is widely used in applications requiring purity, durability, and resistance to harsh environments.

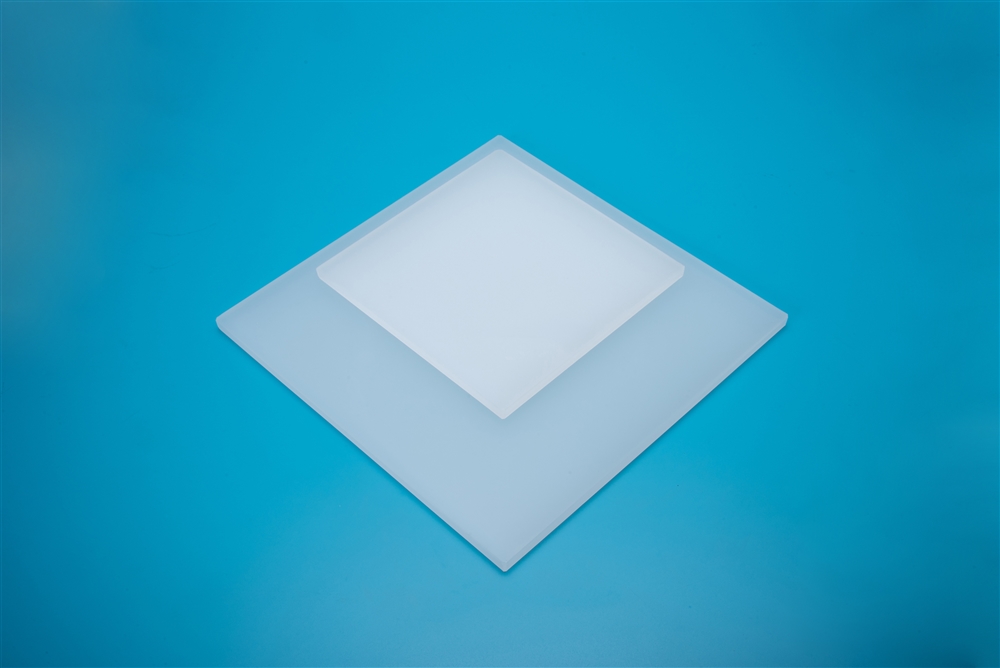

Standard Thickness (mm):

2 ~ 50

Standard Length (mm):

1000 X 2000, 1500 X 3000 mm, 1220 X 2440

TYPICAL PHYSICAL PROPERTIES

Apparent Density 1.78 g/cm3

TENSILE STRENGTH 48 MPa

ELONGATION 18 - 40 %

Service Temperature - 30 To 140 C

Main Performance

Excellent chemical resistance and abrasion resistance

UV stability

Flame Resistant

Used for Tank liners, pump valves, water treatment and semiconductor industries.

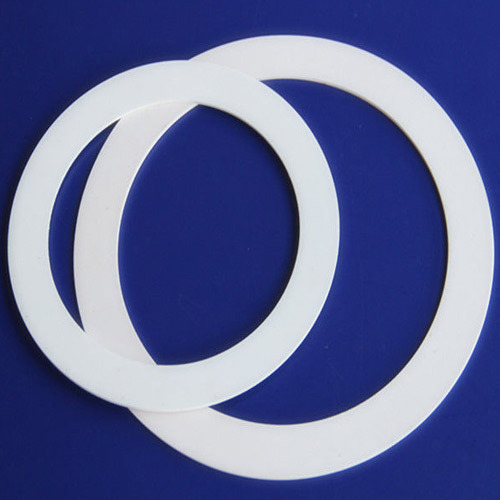

Application

Chemical Processing

Semiconductor & Electronics

Water & Wastewater treatment

Pharmaceutical & Biotech

Oil & Gas

FAQs of PVDF Sheet:

Q: What is the density of the PVDF Sheet?

A: The density of the PVDF Sheet is 1.78 g/cm.Q: Can the PVDF Sheet provide corrosion protection?

A: Yes, the PVDF Sheet offers corrosion protection.Q: What is the working temperature of the PVDF Sheet?

A: The PVDF Sheet has a working temperature of up to 140C.Q: What sizes are available for the PVDF Sheet?

A: The PVDF Sheets are available in different sizes.Q: What material is the PVDF Sheet made of?

A: The PVDF Sheet is made of PVDF (Polyvinylidene fluoride).Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PTFE Sheets' category

|

SANGHVI TECHNO PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |