- Home Page

- Company Profile

-

Our Products

- PTFE Sheets

- PTFE Molded Sheet

- 3 mm PTFE Expanded Sheet

- White PTFE Skived Sheet

- 6 Mm PTFE Sheet

- 1000 Mm PTFE Skived Sheet

- 600 Mm PTFE Skived Sheet

- 1200 Mm PTFE Sheet

- 600 Mm Skived PTFE Sheet

- 450 Mm PTFE Skived Sheet

- 300 Mm PTFE Molded Sheet

- 5 Mm Expanded PTFE Sheet

- 450 Mm PTFE Sheet

- Expanded PTFE Sheet

- White Expanded PTFE Sheet

- 3 Mm Thick PTFE Sheet

- PTFE Sheet

- PTFE Sheet 6mm

- PTFE Sheet 8mm

- PCTFE SHEET

- PVDF Sheet

- PFA Sheet

- FEP Sheet

- PTFE Bushes

- PTFE Rods

- PTFE Tubes

- PTFE Gaskets

- PTFE Machined Components

- PTFE Plate

- PTFE Washers

- PTFE Ball

- PTFE Bellow

- Turcite Sheet Roll

- PTFE Seals

- PTFE Bar

- PTFE Skived Sheet

- Teflon Sheets

- Teflon Rods

- PTFE O Ring

- Bridge Bearing Pads

- PEEK Rod

- PEEK Products

- PTFE Sheets

- Extra Links

- Contact Us

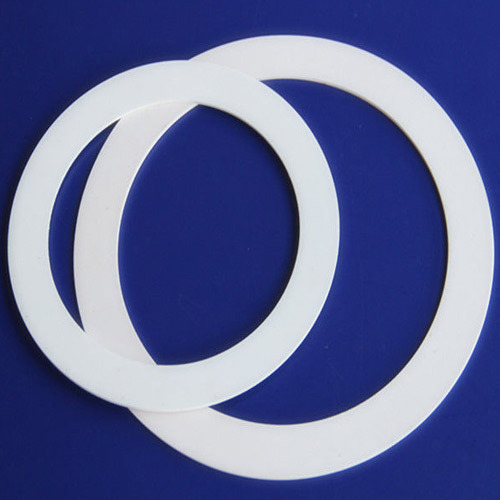

PTFE Filler Gasket

750 INR/Kilograms

Product Details:

- Pressure Resistance Up to 100 Bar

- Temperature Resistance Up to 260C

- Working Temperature -200C to +260C

- Gasket Coefficient 0.08 0.12

- Vaccum Range Full vacuum up to 150 psi

- Hardness 6085 Shore D

- Standard ASME, DIN, BS, and custom standards

- Click to View more

X

PTFE Filler Gasket Price And Quantity

- 10 Kilograms

- 750 INR/Kilograms

PTFE Filler Gasket Product Specifications

- 0.5 mm to 5 mm

- Chemical, pharmaceutical, food processing, and petrochemical industries

- ASME, DIN, BS, and custom standards

- Full vacuum up to 150 psi

- 6085 Shore D

- Stainless Steel, Carbon Steel, or as required

- Ring / Gasket / Custom shapes

- Acids, alkalis, gases, and solvents

- Up to 260C

- Up to 100 Bar

- Standard and customized sizes available

- PTFE (Polytetrafluoroethylene) with Filler

- Stainless Steel, Carbon Steel, or as required

- -200C to +260C

- 0.08 0.12

PTFE Filler Gasket Trade Information

- 10 Kilograms Per Day

- 1-2 Week

Product Description

PTFE Filler Gasket offered by our company, is made using a Teflon or PTFE materials. This gasket provides a wear-resistant seal for gaps between machine parts on applications in various industries. This gasket is very easy to use as well as simple to maintain. This gasket is very effective and economical in nature. PTFE Filler Gasket requires very low maintenance and replacement costs. This gasket is tested under various parameters to ensure its high quality and excellent performance.

PTFE Filler Gasket Technical Details

Standard | ASME, ANSI |

Brand | STP |

Shape | Round |

Temperature | 250 deg C |

Technique | Machined |

Density | 2.1 gm/cm3 |

Material | Compound filled PTFE |

Usage/Application | Mechanical Seal |

Superior Chemical and Thermal Resistance

Engineered with high-purity PTFE and specialized fillers, our gasket offers exceptional resistance to acids, alkalis, solvents, and temperatures up to 260C. This makes it ideal for applications in aggressive chemical environments and diverse industrial operations.

Custom-Crafted Durability and Safety

The gaskets design supports a wide array of sizesboth standard and customizedand meets global standards such as ASME, DIN, and BS. Its self-extinguishing fire resistance and high dielectric strength (>60 kV/mm) enhance operational safety and ensure reliable insulation.

Effortless Installation and Unlimited Shelf Life

Thanks to their smooth surface finish and robust composition, PTFE filler gaskets are easy to install between flange faces with minimal maintenance. Their unlimited shelf life (when properly stored) ensures long-term cost-effectiveness and readiness for immediate deployment.

FAQs of PTFE Filler Gasket:

Q: How is the PTFE Filler Gasket installed between flange faces?

A: The PTFE Filler Gasket is designed for easy installation; simply position it between the mating flange faces, align carefully, and tighten the bolts evenly to achieve optimal sealing. No special tools or techniques are required, granting quick and straightforward assembly.Q: What types of industries can benefit from using PTFE Filler Gaskets?

A: Industries such as chemical processing, pharmaceuticals, food production, and petrochemicals benefit greatly due to the gaskets excellent chemical resistance, temperature endurance, and leak-proof sealing properties.Q: When should I choose a PTFE Filler Gasket over other types?

A: Select a PTFE Filler Gasket when you require outstanding chemical compatibility, high temperature resistance (up to 260C), low water absorption, and superior sealing in aggressive or clean process environments.Q: Where are PTFE Filler Gaskets most commonly used?

A: These gaskets are widely used in pipelines, reactors, pumps, and vessels that handle acids, alkalis, gases, and solvents within industries including pharmaceuticals, food processing, and chemical plants.Q: What is the advantage of the gaskets self-extinguishing fire resistance?

A: The self-extinguishing property ensures that the gasket will not propagate flames, adding an extra measure of safety in high-risk industrial operations and helping meet stringent fire safety regulations.Q: How does the PTFE with filler material enhance the gaskets performance?

A: Added fillers increase mechanical strength, reduce cold flow, improve sealing under pressure (up to 100 Bar), and enhance durability while maintaining PTFEs chemical and low-friction benefits.Q: What benefits does the smooth, low-friction surface provide?

A: This surface finish promotes leak resistance, minimizes flange damage during assembly, and reduces friction, which helps protect both the gasket and the connected equipment over long-term use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PTFE Gaskets' category

|

SANGHVI TECHNO PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |