- Home Page

- Company Profile

-

Our Products

- PTFE Sheets

- PTFE Molded Sheet

- 3 mm PTFE Expanded Sheet

- White PTFE Skived Sheet

- 6 Mm PTFE Sheet

- 1000 Mm PTFE Skived Sheet

- 600 Mm PTFE Skived Sheet

- 1200 Mm PTFE Sheet

- 600 Mm Skived PTFE Sheet

- 450 Mm PTFE Skived Sheet

- 300 Mm PTFE Molded Sheet

- 5 Mm Expanded PTFE Sheet

- 450 Mm PTFE Sheet

- Expanded PTFE Sheet

- White Expanded PTFE Sheet

- 3 Mm Thick PTFE Sheet

- PTFE Sheet

- PTFE Sheet 6mm

- PTFE Sheet 8mm

- PCTFE SHEET

- PVDF Sheet

- PFA Sheet

- FEP Sheet

- PTFE Bushes

- PTFE Rods

- PTFE Tubes

- PTFE Gaskets

- PTFE Machined Components

- PTFE Plate

- PTFE Washers

- PTFE Ball

- PTFE Bellow

- Turcite Sheet Roll

- PTFE Seals

- PTFE Bar

- PTFE Skived Sheet

- Teflon Sheets

- Teflon Rods

- PTFE O Ring

- Bridge Bearing Pads

- PEEK Rod

- PEEK Products

- PTFE Sheets

- Extra Links

- Contact Us

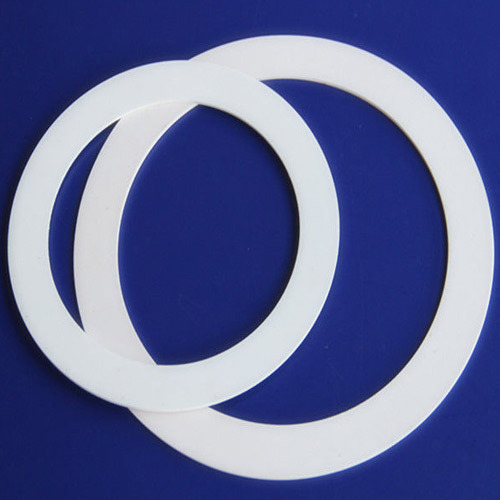

White PTFE Gaskets

750 INR/Kilograms

Product Details:

- Vaccum Range Full vacuum to pressure applications

- Pressure Resistance Up to 100 bar

- Working Temperature -200C to +250C

- Medium Suitable for aggressive chemicals, acids, solvents, alkalis

- Gasket Coefficient Compressibility 7-12%

- Standard ASTM / DIN / IS compliant

- Hardness 55-60 Shore D

- Click to View more

X

White PTFE Gaskets Price And Quantity

- 750 INR/Kilograms

- 10 Kilograms

White PTFE Gaskets Product Specifications

- Full vacuum to pressure applications

- -200C to +250C

- 1 mm to 5 mm

- Not Included / Optional

- Round / Ring

- Up to 100 bar

- ASTM / DIN / IS compliant

- Compressibility 7-12%

- Industrial sealing, chemical industry, pipeline flanges

- Suitable for aggressive chemicals, acids, solvents, alkalis

- Virgin PTFE (Polytetrafluoroethylene)

- 55-60 Shore D

- Up to 250C

- Not Included / Optional

- Custom sizes available (Standard size: 10 mm to 500 mm OD)

White PTFE Gaskets Trade Information

- 10 Kilograms Per Day

- 1-2 Week

Product Description

PTFE Gasket is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. PTFE can be modified for use as a gasketing material with strong chemical resistance properties. This gasket is specified for medical or electrical applications. PTFE sheet gasket material comes in several forms. The first thing that must be determined is what type of PTFE Gasket material youre looking for. The first and most common form is a virgin Polytetrafluoroethylene Gasket material. Virgin PTFE Most applications however are not medical or electrical and can easily be satisfied with mechanical grade PTFE. This gasket is very cost effective and can be easily purchased by our eminent customers at nominal pricing, in bulk quantities.

PTFE Gasket Technical Details

Usage/Application | Sealing |

Brand | STP |

Shape | Flat Gasket |

Temperature | 250 |

Density | 2.1 gm/cm3 |

Product Type | Machined |

Style | Ready cut |

Finishing | Smooth |

Color | White |

Material | PTFE / Teflon |

Exceptional Chemical & UV Resistance

White PTFE gaskets provide outstanding resistance to nearly all chemicals and feature high UV resistance. This makes them an excellent choice for chemical processing, petrochemical, and pharmaceutical industries, where exposure to harsh substances and environmental factors is routine.

Reliable Performance in Extreme Conditions

Engineered to withstand temperatures from -200C to +250C and pressures up to 100 bar, these gaskets maintain sealing integrity in demanding environments. Their non-flammable composition and low water absorption add to their reliability in both vacuum and pressure applications.

Versatile Customization and Standards Compliance

Available in standard outer diameters from 10 mm to 500 mm and customizable sizes, PTFE gaskets are manufactured to suit specific industrial needs. Both ASTM, DIN, and IS standards are adhered to, ensuring consistency and quality for varied applications.

FAQ's of White PTFE Gaskets:

Q: How are White PTFE gaskets installed in pipeline flange applications?

A: White PTFE gaskets are typically placed between the mating surfaces of pipeline flanges to provide an effective seal. Installation involves aligning the gasket, ensuring proper surface cleanliness, and tightening the flange bolts to recommended torque values.Q: What benefits do White PTFE gaskets offer for industrial chemical sealing?

A: These gaskets deliver excellent resistance to aggressive chemicals, acids, and solvents, maintaining integrity across extreme temperature and pressure ranges. Their virgin PTFE material guarantees non-reactivity and reliable sealing performance, reducing maintenance and downtime.Q: When should I choose White PTFE gaskets over other gasket materials?

A: White PTFE gaskets are ideal when you need strong chemical resistance, non-flammability, low water absorption, and stability under high temperatures or pressures. They excel in chemical, pharmaceutical, and industrial settings with exposure to corrosive media.Q: Where can custom-sized White PTFE gaskets be sourced?

A: Custom-sized White PTFE gaskets can be sourced directly from manufacturers, exporters, and suppliers in India. They typically offer both standard and tailored dimensions to match specific application requirements.Q: What is the process of manufacturing White PTFE gaskets?

A: Manufacturing begins with skiving or molding virgin PTFE to the required thickness (1-5 mm), followed by cutting or machining into the desired round or ring shapes. Quality checks ensure compliance with ASTM/DIN/IS standards and consistent properties.Q: How does the smooth/skived finish benefit the gasket's performance?

A: A smooth or skived finish enhances the gasket's ability to form tight seals, reduces leakage risk, and ensures uniform compressibility. It also minimizes surface irregularities, leading to improved chemical and mechanical resistance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PTFE Gaskets' category

|

SANGHVI TECHNO PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |